Introduction

In the dynamic world of bottle manufacturing, staying ahead of the curve requires a strategic blend of cutting-edge technology and expert technical services. These services play a crucial role in optimizing operations, ensuring quality standards, and fostering innovation within manufacturing units. In this blog, we explore the indispensable contribution of technical services to the bottle manufacturing industry.

-

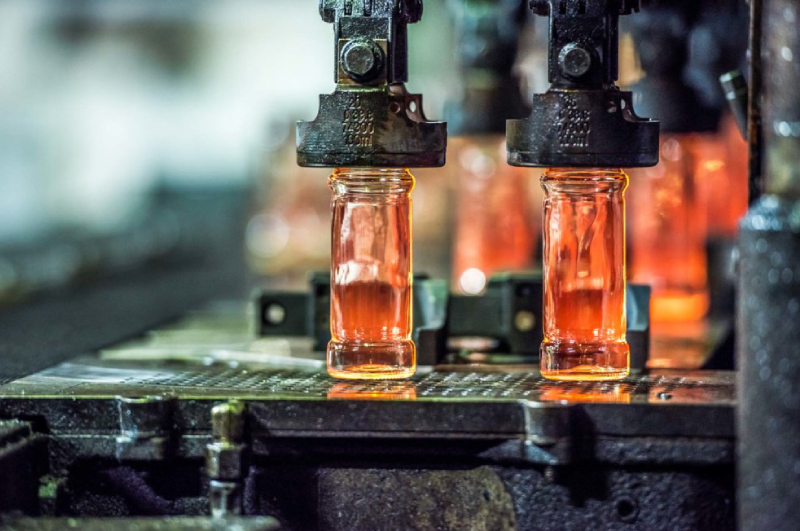

One of the primary functions of technical services in bottle manufacturing units is the calibration and optimization of machinery. Highly specialized equipment, such as glass-forming machines and plastic injection molding systems, require precise settings to achieve optimal production efficiency. Technical experts regularly fine-tune these machines, ensuring they operate at peak performance, minimizing downtime, and maximizing output.

-

As the manufacturing landscape evolves, automation becomes a cornerstone for efficiency. Technical services aid bottle manufacturing units in seamlessly integrating automation solutions into their processes. Automated systems not only accelerate production but also enhance accuracy, reducing the margin of error. From conveyor systems to robotic arms, automation is a game-changer in modern bottle manufacturing, and technical services are instrumental in its implementation.

-

Maintaining stringent quality control is paramount in the bottle manufacturing industry. Technical services contribute significantly to the design and implementation of advanced quality control systems. These systems employ cutting-edge technologies, such as machine vision and sensors, to inspect bottles for defects, ensuring that only products meeting the highest standards reach the market. This proactive approach minimizes waste and enhances overall product quality.

-

To prevent unplanned downtime and extend the lifespan of machinery, technical services implement predictive maintenance programs. By utilizing data analytics and sensors, these services can predict when equipment is likely to fail, allowing for scheduled maintenance before a breakdown occurs. This proactive approach minimizes production interruptions, reduces repair costs, and prolongs the life of critical manufacturing assets.

-

technical services constantly analyze and optimize manufacturing processes to enhance efficiency. whether its fine-tuning production workflows, reducing energy consumption, or streamline material usage, these services aim to create a lean and sustainable manufacturing enviroment. continuous process improvement ensures that bottle manufacturing units remain competitive and adaptable to changing market demands

-

Environmental Sustainability, technical services play a key role in promoting sustainable bottle manufacturing practices. They implement eco-friendly solutions like optimizing energy consumption, minimizing waste generated, and facilitating the use of recycled materials.

-

Technical services teams possess a diverse skillset extending beyond traditional mechanical expertise. They are adept at programming, troubleshooting complex automation systems, and integrating cutting-edge technologies like AI and machine learning.

Conclusion

Technical services are the backbone of innovation and efficiency in bottle manufacturing units. From fine-tuning machinery to implementing advanced automation solutions, these services propel the industry forward. As bottle manufacturing continues to evolve, the collaboration between technical experts and manufacturing units will be integral in navigating the complexities of a rapidly changing technological landscape. Through this collaboration, the industry can embrace the future with confidence, knowing that technical services are at the forefront of progress.